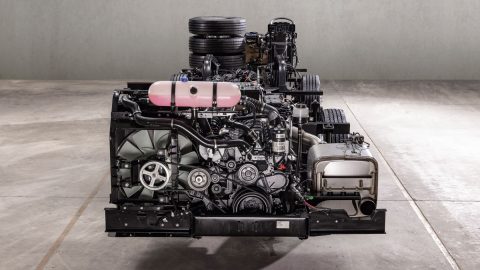

The OM 457 LA BlueTec 5 (Euro V) electronically managed engine is a proven performer in Australian conditions, the 12L engine ensures long life in arduos conditions whilst being economical to operate. The diesel is a water-cooled 6-cylinder in-line engine, vertically mounted, with four-valve cylinder head technology, that is both turbocharged and intercooled. The Electronic Engine Management with individual injection pumps and centrally located six-hole injector nozzles (UPS fuel injection) provide the ideal combination of power and fuel economy.

O 500 RS

Technology

A proven engine for Australian conditions.

A milestone in engine development.

All highway models are equipped with the OM 457 engines which have proven to be reliable long life engines ideally suited to Australian operating conditions. Fuel injection control is based on intelligent monitoring, which provides better combustion, resulting in greater power, greater torque, lower fuel consumption, cleaner emissions and greater durability. In addition, this engine complies with the Euro V Emmissions standard.

A clean performance.

With the BlueTec technology employed by Mercedes-Benz, an optimised combustion configuration minimises the development of harmful particulates from the start and noticeably reduces fuel consumption. Exhaust gas aftertreatment based on SCR ensures the necessary reduction of nitrogen oxides and contributes to a further significant reduction in particulate emissions. As a result the stringent legal requirements of the Euro V standards are combined with low fuel consumption.

Transmission and suspension.

Gearshift comfort.

The O 500 RS engine is equipped as standard with the ZF Ecolife automatic transmission with torque converter. With its six speeds and a topography-dependent gearshift program, it makes for an exceptionally comfortable and fuel-efficient drive in both in urban and extra-urban operation.

With the Mercedes-Benz GO 240-8 automated 8-speed transmission option, the driver can fully focus on traffic – the transmission control takes care of everything else. This innovative transmission system was specifically developed for bus applications and also helps to save fuel.

Integrated cost killer.

Likewise standard: both transmision options come equiped wth an integrated retarder which provides maintenance free braking that relieves the service brake, reduces wear and tear and reduces brake system maintenance costs.

Flexibility on the road.

A driver sometimes has to overcome obstacles on the way to their destination. That's why you can equip the chassis with a pneumatic raising/lowering system to prevent damage to the vehicle's underside when driving over obstacles. This system makes it easier to drive over obstacles or abrupt differences in road surface level as well as making it easier for your passengers to board and to exit the vehicle.

First-class ride comfort.

The front axle of the O 500 RS provides robust performance and premium comfort in the front section. At the same time it stabilises your vehicle body, preventing roll movements and ensuring vehicle track stability. The high-quality front axle increases the vehicle's manoeuvrability, enabling a 12 m vehicle to have a turning circle of 20.60 metres. The ideal complement: the new rear axle. It transfers the driving force to the road with the greatest efficiency and ensures excellent ride comfort with its low-friction, quiet running. The ensemble is rounded off with the actively steered trailing axle for the O 500 RSD. This makes the bus much more manoeuvrable while ensuring maximum straight-line directional stability.

Steering and weights.

Steering with ease.

Drivers favour buses that make their work as easy as possible. The variable-ratio steering gear of the O 500 RS responds to this need. The more the driver turns the steering wheel, the lighter the steering becomes. This makes it possible to steer the vehicle with ease, directly and safely. A plus for handling safety, to which the chassis' particular economic efficiency can be added. The steering system does not need to be lubricated which makes it virtually maintenance-free.

Freedom for bodywork design.

The Mercedes-Benz chassis have been designed, tested and produced to enable maximum flexibilty for bodybuild. Chassis corrosion protection is aided by sealing the welding seams and inside-waxing of square tubes and the chassis frame is completely painted for long-term corrosion protection. This includes providing detailed guidance for bodybuilders, with body mounting positions, system interfaces and to ensure optimal integration between chassis and body.

Interfaces & electronics.

Focused intelligence.

The Mercedes-Benz O 500 RS chassis are vehicles featuring the on-board electronics concept, comprised of electronic control units that are interconnected through a CAN system, which is the digital interface for data communication.

It is a real time communication network, that handles and distributes information and control data. The purpose of the CAN system is to smartly improve data acquisition and handling, as well as to reduce the number of connections and cables between systems, thereby increasing the overall safety of the system.

Technology for the driver.

The Hill Hold function is also standard on the O 500 RS and when activated (via a button on the dashboard), the service brake system remains activated even after the driver's foot has been removed from the pedal. The brake is released when the engine is accelerated by the driver. Especially useful at stops on slopes, it prevents the vehicle moving backwards, improving driver and passenger comfort whilst also reducing driver fatigue.